From Idea to Prototype

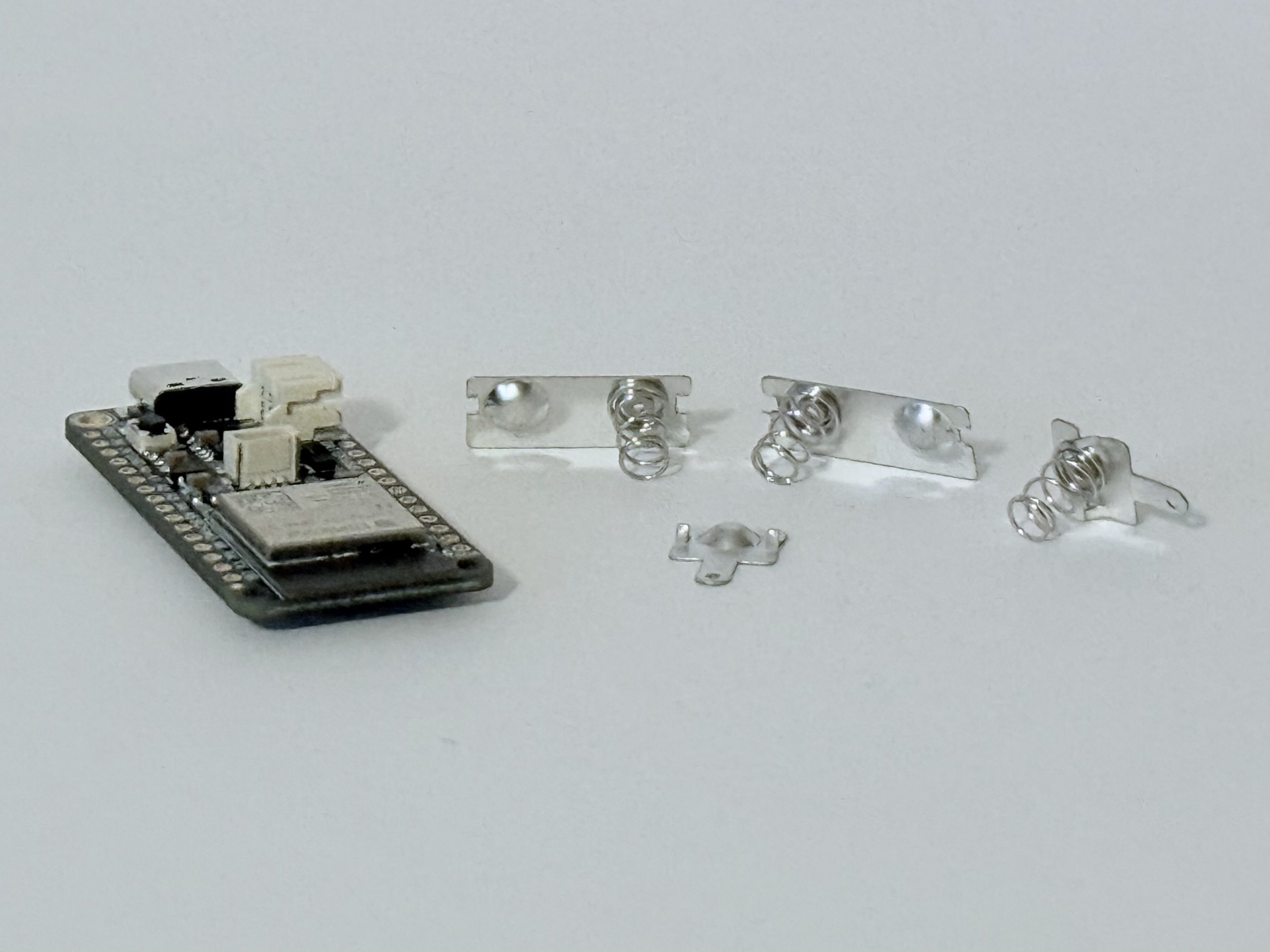

| Requirements & Components

Each project begins with defining specific requirements to shape the product’s design and functionality. Based on these requirements, essential components—such as electronic boards and standard parts—are selected.

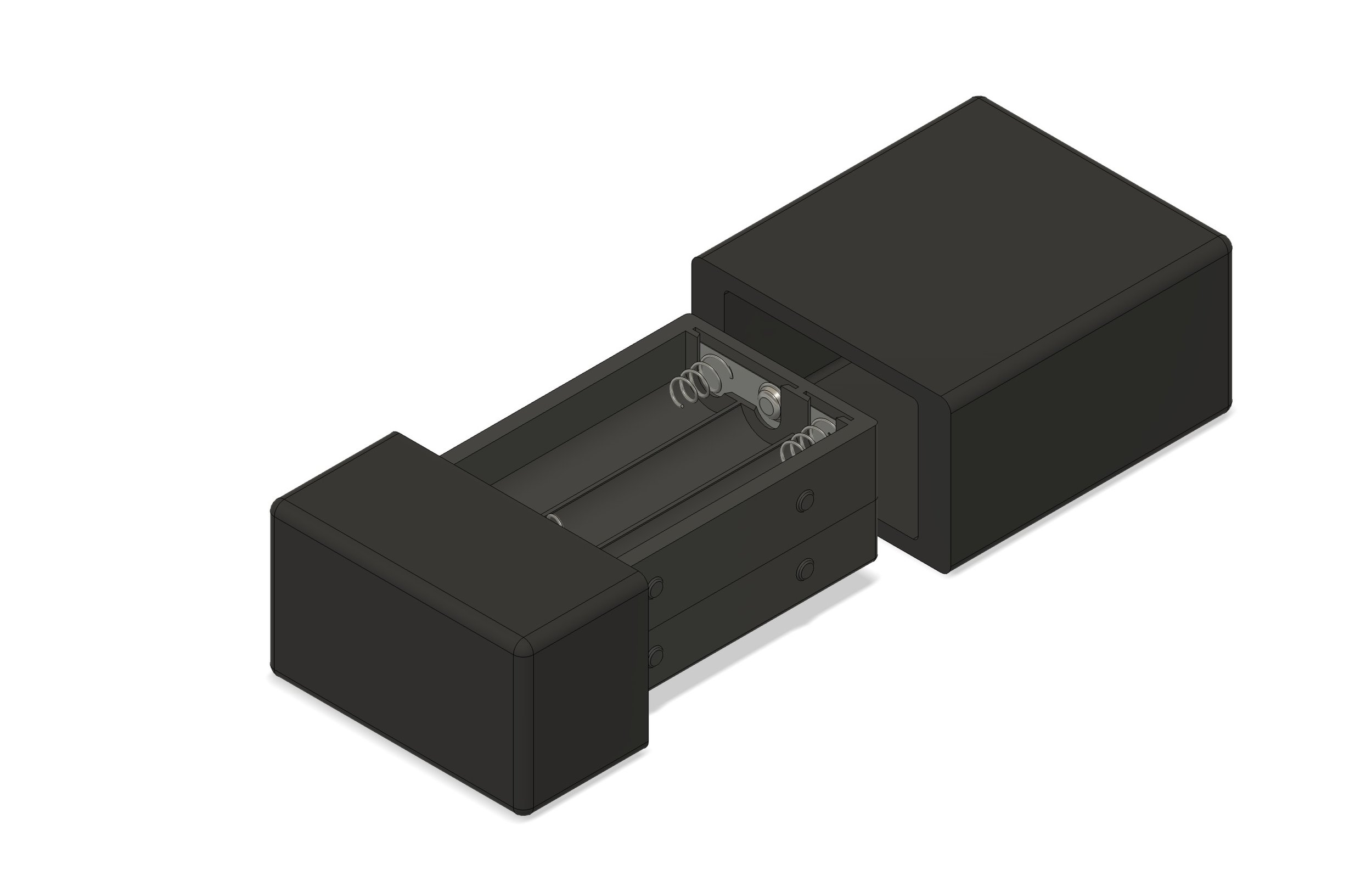

| Design Phase

In the product design phase, parts are arranged in a CAD program, where a custom case is crafted around them, refined to meet 3D printing requirementsfor optimal manufacturability and usability. By leveraging 3D printing, thedesign can incorporate complex geometries and customized features that wouldbe challenging with traditional manufacturing methods.

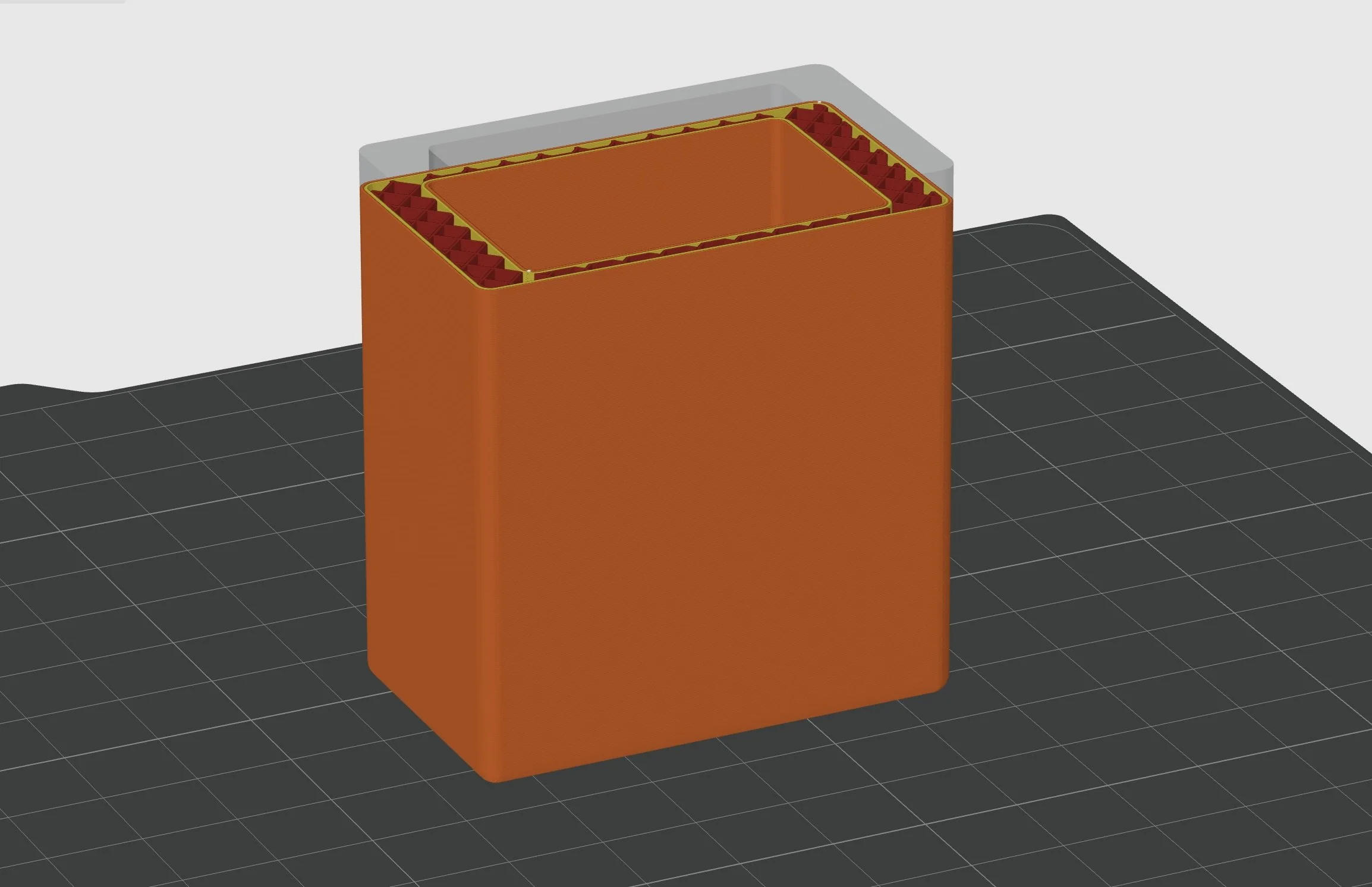

| Production & Assembly

With the design finalized, production of individual parts begins, followed by theassembly of the first prototype. This is where 3D printing excels, enabling rapid production and immediate adjustments.

| Testing & Refinement

The prototype undergoes thoroughtesting for assembly and usability, ensuring each component fits accurately and functions as intended. Based on these tests, the design is iterated upon, withadjustments made to tolerances, assembly efficiency enhanced, and overallusability refined.